Submitted by Administrator on Tue, 22/08/2017 - 00:20

Luke Williams, a undergraduate student from Loughborough Design School in Loughborough University, won the title of the Undergraduate Students Design Competition in July 2017.

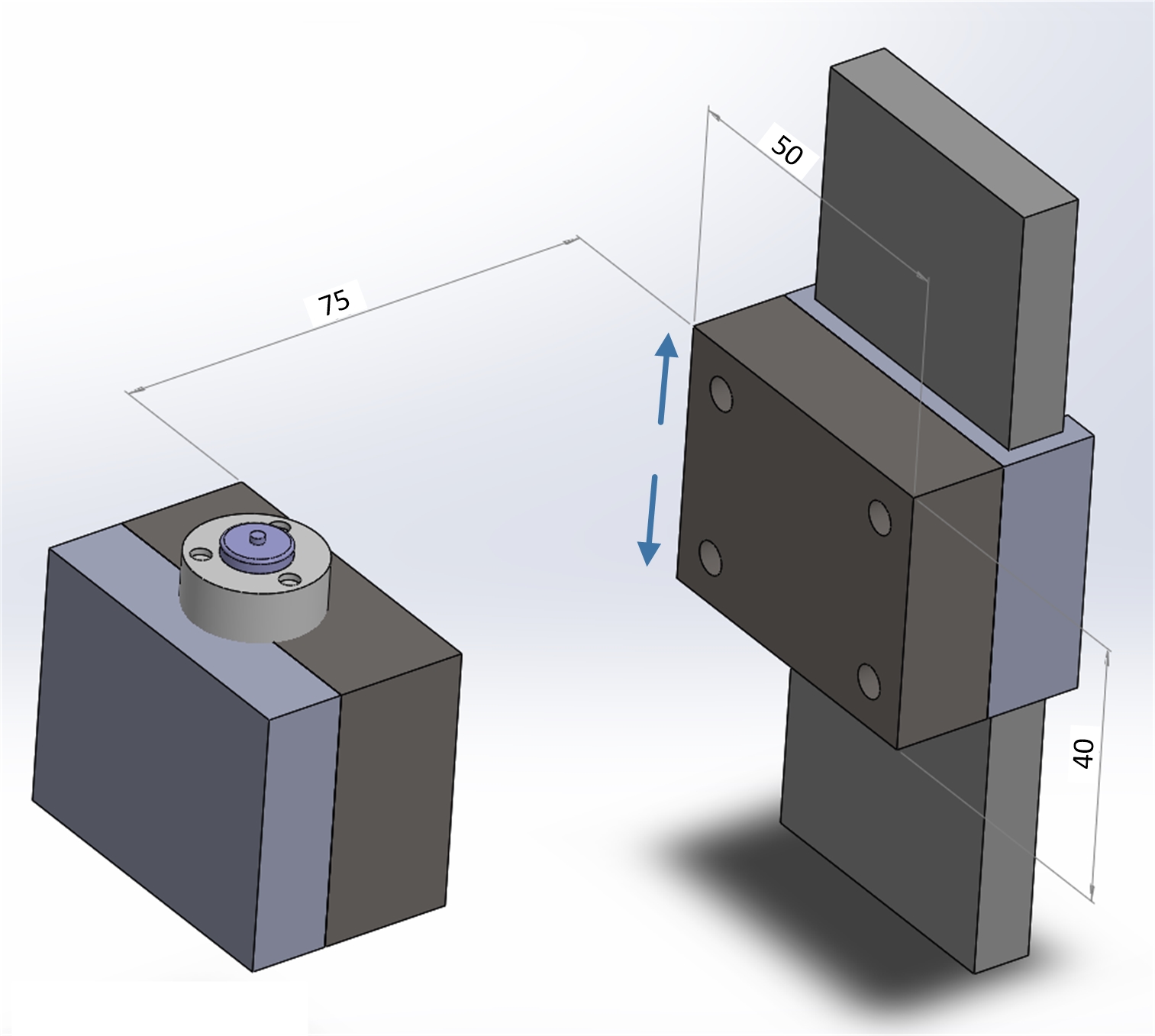

The task of the competition is to design a structure that connects two parts of a scientific instrument as shown in the figure below. The left part holds a load cell, which must be rigidly mounted to the linear bearing on the right to allow it to move freely in a vertical direction. A structure is required to rigidly connect the load cell to the bearing using the existing four bolt holes. The manufacturing method to be used is either Fused Deposition Modelling (FDM) or Selective Laser Sintering (SLS). The materials are ABS for FDM and Nylon for SLS, respectively.

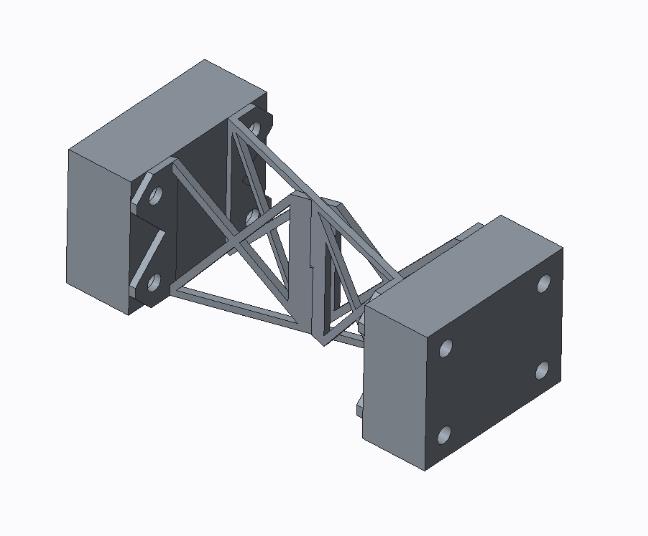

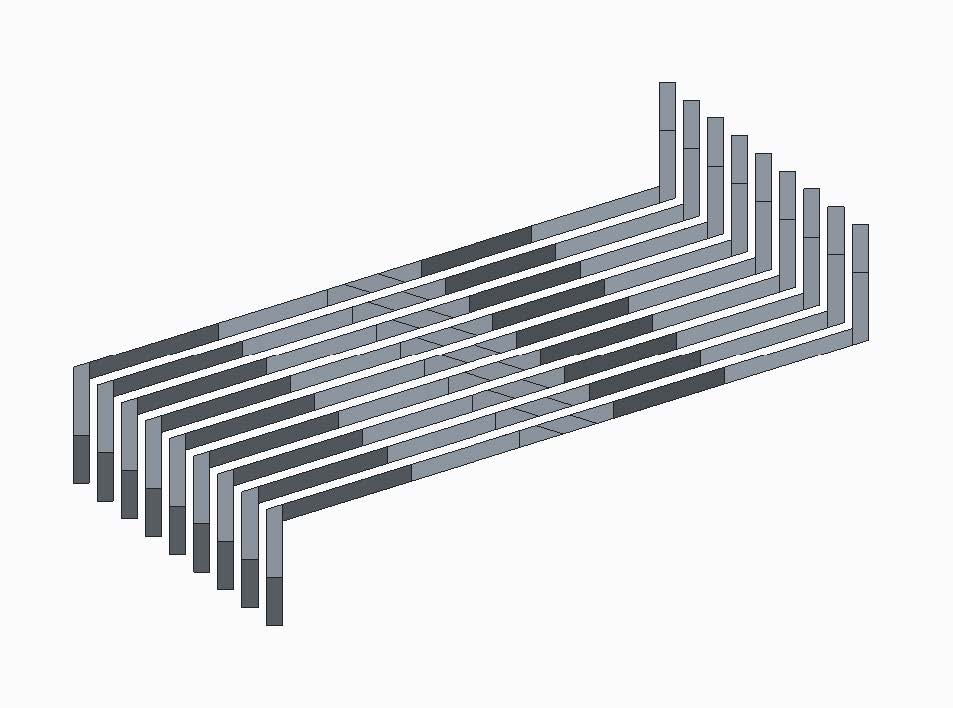

The structure designed by Williams is split into two of the same part to eliminate the need for support material and allows for compact nesting for FDM printing to utilise the maximum available space on the print bed. The two parts interlock to form a rigid structure. All angles are greater than or equal to 45 degrees.

The two parts were printed on a Prusa i3 mk2 with a layer height of

0.15mm.