Overview

The current project “Design for Additive Manufacturing” (hereafter referred to as D4AM) funded under the ‘Design the Future’ phase 1 call in 2014 has established a strong basis for continuation including increasing scope and depth. The constraints of the phase 1 call necessitated a focus on only the two most frequently used Additive Manufacturing (AM) polymer processes, fused deposition modelling (FDM) and laser sintering (LS) whilst we found that other established processes are being used. D4AM-1 established the theoretical framework for design guidance for AM and provided the structure for the data gathering, synthesis and presentation of design guidance that provides the foundations for expanding the work to include other well established AM processes, such as stereolithography and ink-jetting and begin developing design guidance for emerging AM process including multiple-materials (e.g. Object Connex), faster processes (e.g. HP Multi Jet Fusion) and metals.

Findings

- There has been an explosion of academic interest in design for AM and there is a great deal of excitement about the industrial potential of AM amongst government and industry bodies.

- There is still a lack of design experience or expertise and that design guidance for AM or readily available case studies remains extremely limited.

- Design for AM expertise is ad hoc, limited, geographically constrained and based mostly on self-taught, experiential or trial-and-error learning.

- To date much so called design guidance for AM is limited to ensuring “printability”; that is avoiding or adding features to ensure the build process does not fail. Designs following such guidance may be “printable” but have no design optimisation at all.

- More useful design guidance for AM is typically limited to detail design rules that are typically only applied at an individual feature level (e.g. minimum wall thickness) or is focused only on the perceived advantages of AM without due regard for their implications on the design of the whole product.

- Many studies have focused on ultimate capabilities for specific geometric features rather than on reliable, predictable or repeatable tolerances. For example part complexity is frequently espoused as a key advantage despite the fact that the increased complexity may be unnecessary, lead to much slower build times or create difficulties with downstream processes (such as finishing or assembly) resulting in poor manufacturing efficiency and increased cost.

- A large number of the design principles that can be achieved with AM are being applied on a component level rather than a product or assembly level. For example, part consolidation is a key advantage of AM but only where issues such as cost, accuracy, strength, service life, maintenance, repair or replacement have been properly considered.

- There are contradictions in design guidance from different sources. Lack of experimental validation of design guidance to eliminate these contradictions.

- Whilst there is much activity in industrial research and an increasing amount in academia, it is still dominated by aerospace applications and safety critical / weight critical design optimisation for load-bearing metal components. Topology optimisation for example is being widely explored in AM for safety critical applications.

- Industrial research into design for AM is understandably being withheld as intellectual property and commercial advantage, which means that the design guidance being developed is not available for wider education and is not subject to wider scrutiny, validation or adoption. This is being reinforced by consolidation in the industry (e.g. GE taking over both Arcam and Concept Laser). These developments will restrict the adoption and growth of AM across industry, especially amongst manufacturing SMEs.

- Despite these limitations above, there are commercially successful applications of AM for series production of end-use parts, typically very low volume high value components but also some low-value and simple components made in high numbers.

- We surveyed more than 100 designers to determine the desirability of different modes of guidance. The results show that designers prefer online and video formats for the presentation of design guidance.

- The need for a wider consideration of design for AM guidance for other industry sectors and particularly for industrial / product design remains and is now recognised as a potentially limiting factor in the growth and exploitation on AM in UK and European industry.

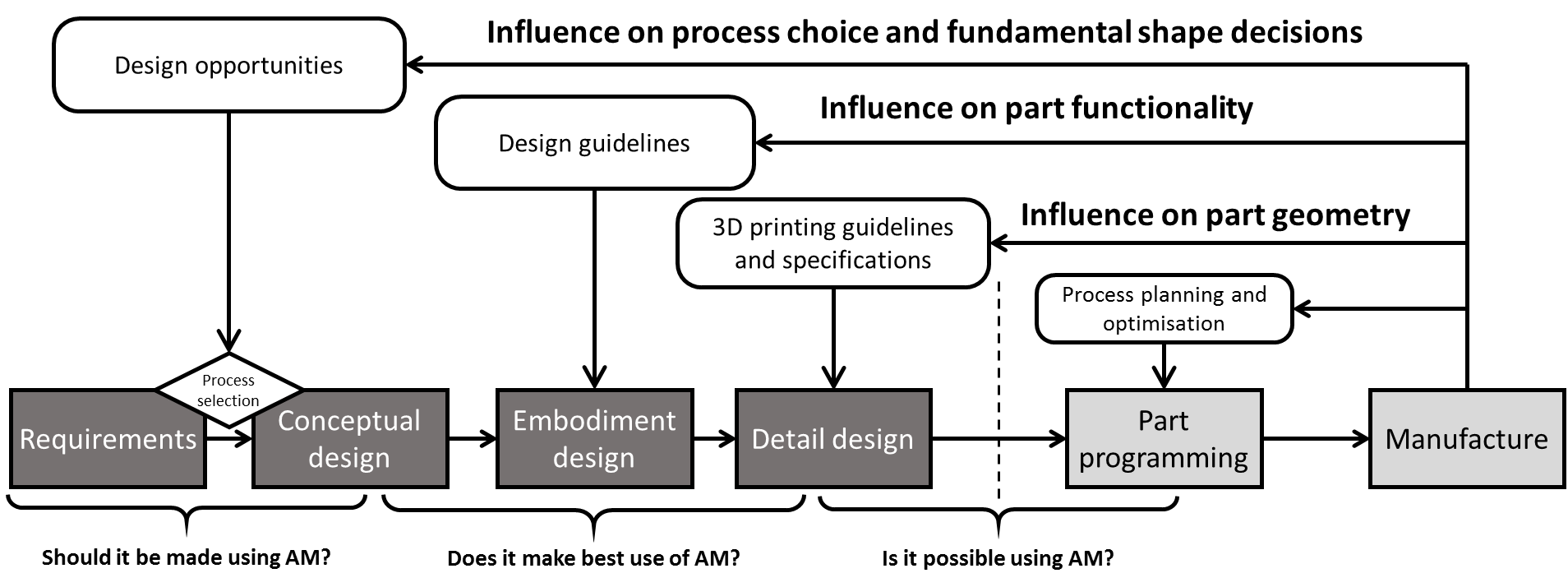

We created a framework to organise the current DfAM knowledge (a simplified version is shown below), highlight gaps and inform future research.